On mechanical agitation, things to look out for are:

- Tanks agitated when they do not need to be (for example, overnight). If the contents are being agitated to prevent constituents settling out, a simple experiment will show whether it is safe to stop agitating outside working hours, and how long it takes to restore proper mixing.

- If tanks are stirred to mix batches of ingredients, has anyone done a study to find out how best to determine the 'end point' of the process? If not, blending times will always have to be longer than necessary.

- Are tanks agitated by compressed air? If so, is clean, dry, high-pressure air from a central compressor being used? The alternative is to use lower-specification air from a local blower. If agitation is required when there are no other uses for compressed air, this will also allow the central plant to run fewer hours.

- Consider using a mechanical stirrer rather than compressed air.

- Assess the design of mechanical stirrer paddles. Better hydrodynamic design could achieve the same mixing effect with less energy.

- Excessive preheat periods

- Tanks heated while idle for long periods

- Lack of insulation not just on the tanks but on associated pipes and fittings

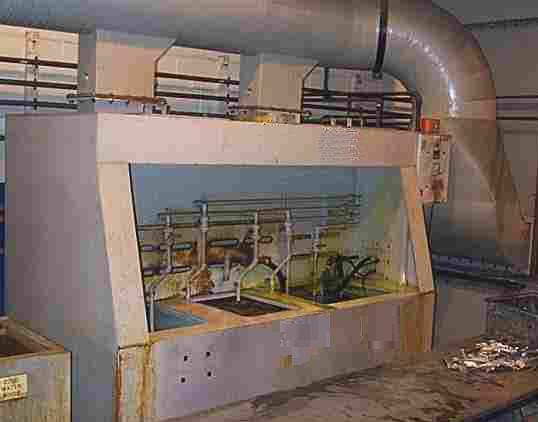

- Lack of lids on tanks. This can be a contentious issue because operators tend not to like them. One way to overcome their objections might be to involve them in the design of a lid system that does not interfere with their work unduly. Remember that effective lids or ball-blankets can reduce heat, humidity and condensation in the working area. Spirax Sarco's on-line learning centre includes a module on heating of tanks and vats which gives a very useful theoretical background.

- Excessive extract air velocities over exposed liquid surfaces

- Continuous uncontrolled top-up and overflow or run to waste.

- Aqueous tank contents boiling when 95°C would be effective.

- Steam blowing through directly-heated tank contents

- Local ventilation extract drawing air from general heated space. Consider whether a local fresh air supply can be ducted in to balance local extract.