Harry R Cripps

Heat recovery flowsheet and control/operability

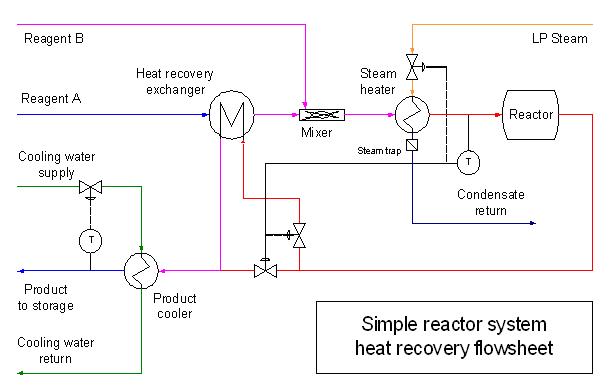

Heat recovery introduces new energy and/or material flows into a process. It is therefore important to anticipate any interactions which might take place. It is also important to control the system in such a manner that the intended energy saving occurs in practice but that it does not adversely affect the main purpose of the process.Even for very simple heat recovery projects, it is strongly recommended that a process conceptual flowsheet is drawn up and the principal control elements shown. This should be standard standard practice for almost any process project but in some companies it is often overlooked.

The first objective of the proposed flowsheet is to provide an unambiguous description of what the project entails and how it is intended to operate. This provides both the project team and the operating team an opportunity to satisfy themselves that it will indeed work as intended and to consider how it may perform under a range of operating conditions.

If the project is more complicated (and sometimes even when it is quite simple) there may be unexpected outcomes which are not necessarily obvious. Therefore a more formal operability review is often desirable. Many companies have existing standards for flowsheet review, others should seek advice if necessary. The author has found that a modified form of Hazop analysis is very effective in the context of heat recovery projects.

Note: An operability review is not a substitute for proper design of the project in the first place. Its objective is to identify potential for occurrences which differ from the design intent. It should be carried out after at least the preliminary flowsheet and control system conceptual design have been prepared.

Return to main heat recovery article