Vilnis Vesma and

Richard Norton

11 January 2008

See also:

Manual meter reading;

Flow metering;

Justifying additional meters

Automatic meter reading

An automatic meter reading (AMR) system will fulfil two distinct requirements: facilitating remote readings, and providing fine-grained consumption histories. AMR is thus beneficial in the following circumstances:- A dispersed estate of multiple sites

- Unattended outposts

- Sites with access restrictions (tenants' areas, hazardous areas)

- Requirement for numerous readings to be synchronised, even if only on a weekly or monthly basis

- Where information is required with minimum delay

- Requirement to monitor consumption within restricted time-bands (for example, to enable time-of-day billing)

Components of AMR systems

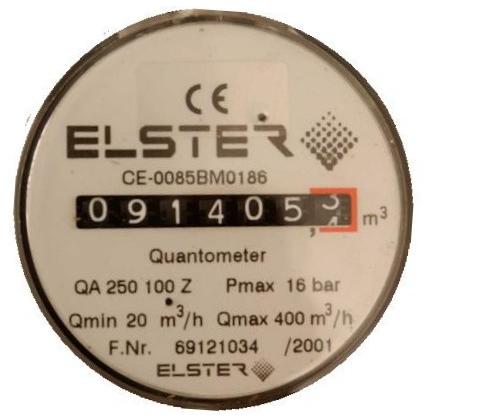

Going from the measured flow to the database, one requires the following components:- A sensing element: e.g. an orifice plate, which provides a physical signal related to the measured flow;

- A transducer: e.g. the differential-pressure sensor and 'flow computer' on an orifice plate, whose job is to turn the physical signal into an electrical one (including converting one electrical signal into another, for example a current into a pulse rate). The sensing-element-and-transducer combination constitutes the 'meter'.

- A data logger, which may be integral with the meter or a separate device, and whose job is to record data for onward transmission (at a minimum this could consist only of a register recording the current value).

- Communications: this could be low powered radio, modems, GSM modems, Local area network or even the internet. In certain circumstances a combination approach may be appropriate, for instance multiple meters on small supplies across a large foot print for instance a complex of flats, may use low power radio as a low cost alternative to installing wiring to each meter. A profile logger / radio receiver may be installed locally as a data concentrator which is in turn web enabled or connected to a telephone line to finally allow data collection to a remote server.

- Data-collection software: the final link in the data acquisition chain, which co-ordinates collection from various logging systems and populates a database with the consumption data. Usually, this software will have only limited analysis and reporting functions, but may have either an open database format for more sophisticated energy management packages to extract data from, or a scheduled data export function to a common format such as comma-separated value (CSV). Certain meter manufacturers may have agreements in place that their loggers or meters can be polled directly by a proper energy management software package which will have the full suite of analysis and reporting built in.

Interfacing to the meter

One common form of interface between the meter and the outside world is a pulse output in the form of a volt-free contact (on/off switch) which is closed briefly each time a predetermined quantity is registered by the meter. The pulse-output contact may be built into the meter, or it may be an optional fitting. Versatile 'bolt-on' pulse interface units, often with an optical sensor, are also available which can be attached to conventional meters where there is no other provision. Pulse outputs provide a simple standard interface, but are limited to only relaying one metered parameter per twisted pair and, where a reed switch is the means of generating a pulse, have a limited life span depending on the pulse frequency.It is usual for the pulse outputs from meters to be fed to a data logger which records the number of pulses received during successive fixed time intervals. Such a logger may be integral with the meter (as is the case with Code 5 half-hourly electricity meters) or an external device may be used. Building energy management systems (BEMS) are sometimes used for data logging but when busy on control tasks they can miss pulses. The physical data link from a meter logger to its database computer may be a simple serial (RS232 or RS485) connection but there are many other options on the market, including low-power radio (LPR), GSM mobile phone technology, and Ethernet, the ubiquitous local-area network (LAN) technology.

An alternative to pulse-counting is serial communications interface direct to the meter. Often promoted as 'the result of recent advances in metering' or 'new technology', so-called smart metering has been around in the form of the Modbus protocol for over 25 years. Newer protocols such as Profibus, Fieldbus and Mbus offer further advantages in terms of improved network performance and the ability for communication to be initiated in either direction (for example, exceptions can be reported by the meter rather than having to wait for the meter to be polled by a network master device). Typically meters will be connected to a local area network using one of the above proprietary protocols and then in turn connected to a wider Ethernet intranet or the internet via a gateway device. Some modern meters have Ethernet capability integrated into their design, obviating an intermediate gateway device and some models also double as pulse profile logger offering a limited number of pulse inputs for water and gas meters, providing an integrated solution in one easy to install package.

A serial interface offers the further advantage of being able to carry data for any parameter that the metering system is capable of measuring which could be power factor, instantaneous voltages and currents etc for an electricity meter but also flow rate, pressure and temperatures etc. for heat and steam meters. This means that more added value is returned from the investment in sensors for a metering system through providing engineers with more detailed information other than simply consumption data alone. 'Smart metering' also provides the ability to capture transient behaviour through offering the ability to log at very high frequencies. Furthermore, the resolution of the data is limited only by the resolution of the meter register rather than a fixed increment dictated by the pulse value which is often selected to represent a large chunk of consumption in a trade off between resolution and extended life expectancy of the pulse generating device. The ability to read the meter register directly removes the need for an intermediate pulse counter that requires synchronisation, eliminates the risk of missed pulses and can easily be interpolated to fill gaps where communications have failed, thereby improving the overall quality of the data. One final advantage to add in the case for serial communications against a pulse output is that where a number of meters are installed in one place such as in an electricity switch room, installing a communications bus rather than a twisted pair between each meter and a pulse logger reduces the amount of wiring and is more easily expandable, becoming far more cost effective as the number of meters increases.

Data communications

The choice of communications technique will be dictated by the circumstances of the individual application. A compact factory site with Ethernet cabling suggests one solution, whereas a large airfield, for example, might call for LPR communications; a dispersed estate of unattended remote installations such as pumping stations might require GSM technology. In choosing a technology it is important to understand the objectives of the exercise and to ensure, for example, that data transmission rates are not raised unnecessarily by choosing too short a datalogging interval. It would make no sense to log and transmit data at ten-minute intervals if daily totals would suffice. Remember that the reason for an AMRS may be merely to facilitate synchronous readings from remote or inaccessible meters; frequency of reading may not be important.Making progress

Users should not be paralysed by the seemingly overwhelming choice of communication options as in most cases decisions are not binding. Indeed many large organisations will have a diversity of scenarios relating to meter locations and it is likely that only through combining different options will needs be met in the most cost effective way. Most reputable providers of data collection systems will have a suite of solutions at their disposal to deploy according to the demands of each physical metering location, so do not be tempted into thinking there is a 'one size fits all' option.The final point to make is this: although the suppliers of AMR solutions often offer monitoring and targeting software (and may even bill their wares as 'automatic monitoring and targeting'), analysis and reporting is not where their strengths lie. If contemplating building a monitoring and targeting system from scratch with automatic meter reading, your interests will be best served by splitting the project into two:

- Metering, data collection and communications; and

- Analysis and reporting functions